The confluence of 5G networks, AI and machine learning, industrial IoT, and edge computing are driving the fourth industrial revolution – Industry 4.0. The impact of the industrial edge and how it is being transformed were among the topics at our SNIA Cloud Storage Technologies Initiative (CSTI) webcast “5G Industrial Private Network and Edge Data Pipelines.” If you missed it, you can view it on-demand along with the presentation slides in the SNIA Educational Library. In this blog, we are sharing and clarifying answers to some of the intriguing questions from the live event.

Q. What are some of the key challenges to support the agility and flexibility requirements of Industry 4.0?

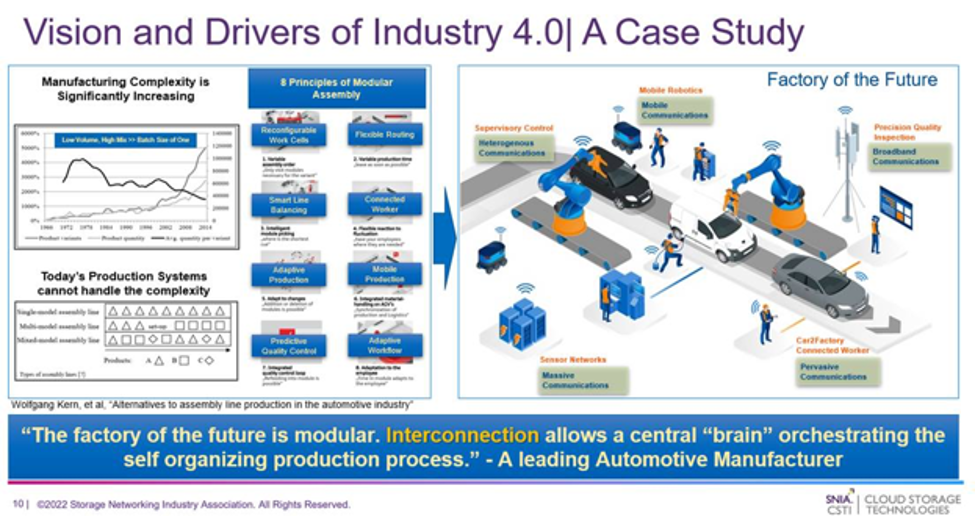

A. The fourth industrial revolution aka Industry 4.0 aspires to fundamentally transform the flexibility, versatility and productivity of future smart factories. Key attributes of this vision include complex workloads to enable remote autonomous operation, which involves autonomous mobile robots and machines, augmented reality aided connected workers, wireless sensors, actuators and remote supervisory control systems, as shown in the diagram below. Machines in smart factories will no longer be stationary. To enable quick response to supply demand changes and enable mass customization (“batch size of one”), factory lines need to be quickly reconfigurable and need machines to move within a certain range. These AI-based, mobile autonomous robots and machines require high data through-put wireless networks and highly reliable sub-second latency for machine-to-machine control communications.

Q. What are some of the new 5G capabilities that are important to enable Industry 4.0?

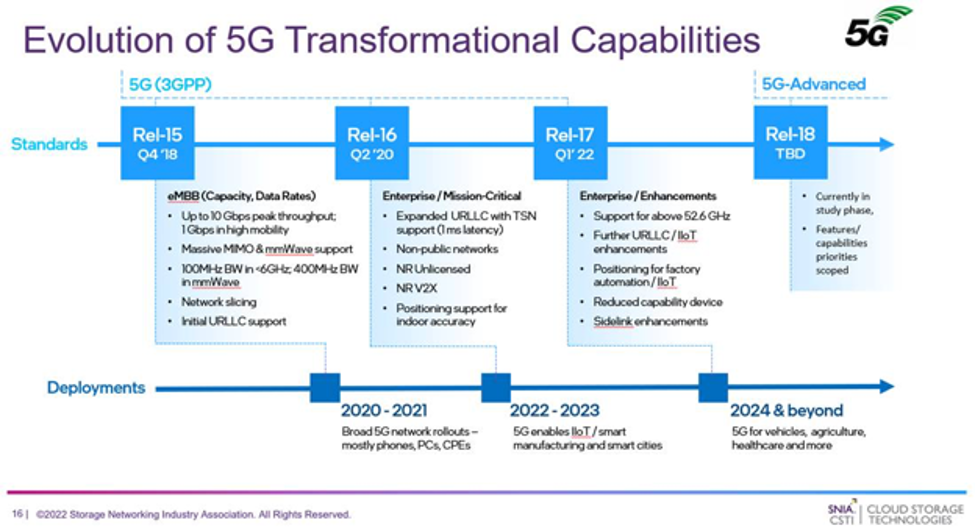

A. Although cellular technology (2G through 4G) was primarily targeted to serve consumers via massive public networks, 5G enables standalone private networks and is designed to meet the needs of vertical industries. Not only does 5G provide faster data rates (up to 10x faster than 4G), but 5G also supports delivery of massive amounts of concurrent machine-to-machine connections. With 5G private networks, users can tune the network based on custom requirements of the factory. Providing enhanced design flexibility, network slicing establishes multiple logical/virtual networks to handle a wide variety of use cases, all coexisting on the same physical infrastructure. Here are a few of the transformational 5G developments, as shown in the diagram below.

- Enhanced Mobile Broadband (eMBB) supports extremely high data rates (up to several Gb/s) and offers enhanced coverage beyond existing networks

- Massive Machine Type Communication (mMTC) supports wide-area coverage, signal penetration through indoor structures, ubiquitous connectivity enabling hundreds of thousands of IoT devices per square kilometer and support for battery-saving low energy operation

- Ultra-reliable Low Latency Communications (URLLC) supports high reliability applications requiring low-latency end-to-end communications

Q. What does this all mean for storage?

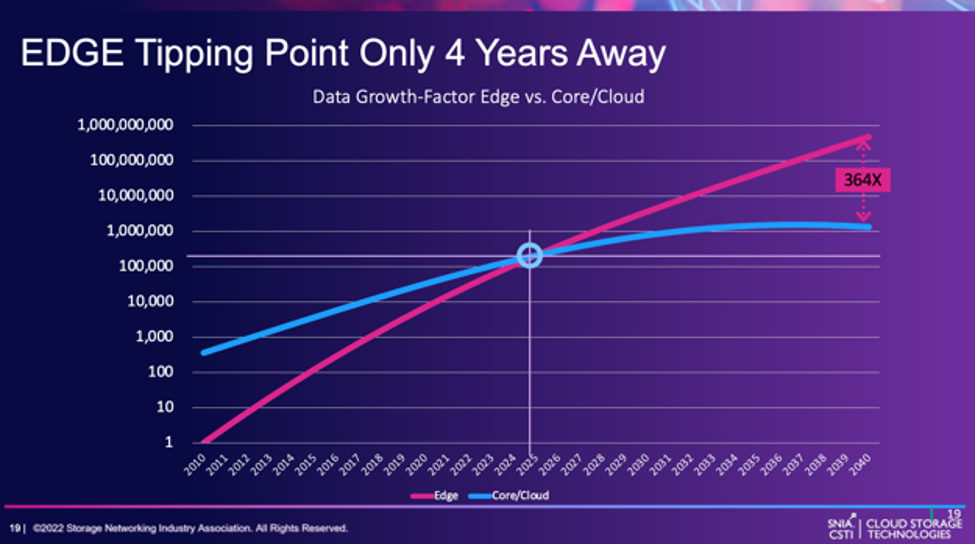

A. There is a huge shift now that 50% of data is being created and processed at the edge. It’s really putting us at a tipping point (as demonstrated by the chart below). By the time we get to the year 2040, it is projected that there will be 364 times the amount of storage growth at the edge compared to data centers. Our mission as storage professionals is to start looking at how we place our technology and how we think about data and data movement within our organizations.

The bottom line: Storage and data strategies must include the edge.